Difference between revisions of "Macsys Holding BV"

| Line 1: | Line 1: | ||

| − | + | [File:Macsys-logo.png|right|400px]] | |

| − | + | ||

| + | |||

| + | == 3d Printing [2006-2011] == | ||

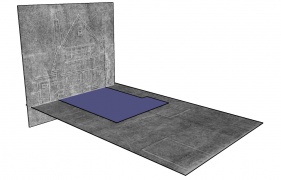

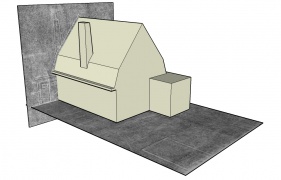

| + | [[File:valkbouwmanlaan.jpg|thumb|450px|''Macsys's pilot project; 3d printed house on wooden pedestal. Details are in the 0.8-1mm range, layer step size is 0.2mm'']] | ||

| + | '''Macsys''' was founded as a [https://en.wikipedia.org/wiki/General_partnership General Partnership] (Dutch V.O.F.) on 13 October 2006 by André Schalkwijk and Marcel Alfons. The name '''Macsys''' is inspired by CAM software [https://en.wikipedia.org/wiki/Cimatron Cimatron], where MACSYS stands for Machine Coordinate System. '''Macsys''' uses [https://en.wikipedia.org/wiki/SketchUp SketchUp] software to transform architectural 2d drawings into 3d surface models. The 3d surface models are fed into [https://en.wikipedia.org/wiki/Z_Corporation Z-Corp] printers to create tangible solid models or [https://en.wikipedia.org/wiki/Maquette maquettes]. Z-Corp printers use [https://en.wikipedia.org/wiki/Inkjet_technology inkjet-technology] to create full color models, making them ideal for visualization. | ||

| + | |||

| + | Traditionally, [https://en.wikipedia.org/wiki/Architectural_model architectural models] are handmade using various materials. These materials have a look and feel that is close to the finished building, something that can not be achieved with 3d printing. The benefit of 3d printing is speed. A virtual 3d model is created faster and in finer detail then hand crafted models, especially if the building design is available digitally. Because 3d printed models are build up in layers, the surface finish is inferior to traditional models. The surface finish however can be improved by sanding or bead blasting. | ||

| + | |||

| + | |||

| + | <gallery mode="packed"> | ||

| + | File:2dscan-achtergevel.jpg|''scanned 2d drawing'' | ||

| + | File:Iso backandfloorplan.jpg|''ISO-view of both facade- and floor-plan in SketchUp'' | ||

| + | File:Isoback-buildup.jpg|''constructing the 3d model with push-pull tools'' | ||

| + | File:Final detail.jpg|''finalized 3d model including shadow and sketched lines effect'' | ||

| + | </gallery> | ||

Revision as of 08:49, 28 September 2019

[File:Macsys-logo.png|right|400px]]

3d Printing [2006-2011]

Macsys was founded as a General Partnership (Dutch V.O.F.) on 13 October 2006 by André Schalkwijk and Marcel Alfons. The name Macsys is inspired by CAM software Cimatron, where MACSYS stands for Machine Coordinate System. Macsys uses SketchUp software to transform architectural 2d drawings into 3d surface models. The 3d surface models are fed into Z-Corp printers to create tangible solid models or maquettes. Z-Corp printers use inkjet-technology to create full color models, making them ideal for visualization.

Traditionally, architectural models are handmade using various materials. These materials have a look and feel that is close to the finished building, something that can not be achieved with 3d printing. The benefit of 3d printing is speed. A virtual 3d model is created faster and in finer detail then hand crafted models, especially if the building design is available digitally. Because 3d printed models are build up in layers, the surface finish is inferior to traditional models. The surface finish however can be improved by sanding or bead blasting.